Beyond the main components and assemblies, your production may include many hundreds of other items from different suppliers – fasteners, connectors, electronic components, switches and so on. Many of these are used in some volume across the range of your production; others may be specific to less common products. They may be entirely generic, or tightly specified, perhaps to the proprietary designs of a single manufacturer. (Some may even be bought-in parts to your own design). Typically, though not invariably, they are small both in size and in price, though their total value may be considerable, and although they are critical to production, your order may be of minor importance to the supplier.

Such parts are by their nature liable to loss, damage and wastage, and often they are required in several different production stages, making control of issue and usage difficult. The length of your tail tends to increase as new products introduce new item variants. Effectively managing this tail requires inordinate administrative time and expenditure with little opportunity to achieve compensatory savings.

Tail supply management

The tail supply of our clients often consists of a fragmented network of suppliers, many order streams, and administrative overhead that drains resources over multiple departments. MAG45 consolidates suppliers, streamlines procurement, and optimizes workflows, ensuring our clients benefit from cost efficiencies and a more resilient supply chain.

By applying Tail Supply Management, we transform what is often an unpredictable and inefficient process into a structured, optimized, and cost-effective procurement strategy, enabling clients to focus on their core business.

Vendor managed inventory

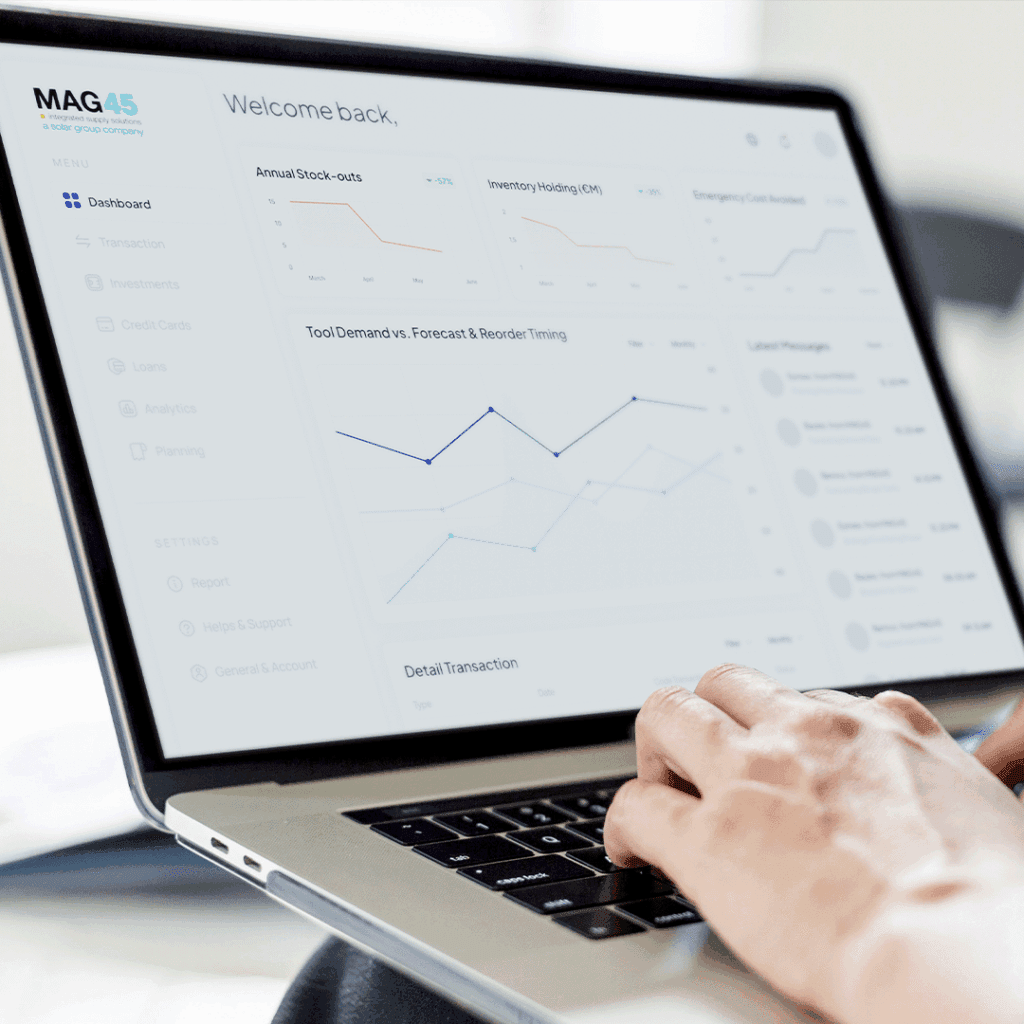

With Vendor Managed Inventory (VMI), MAG45 takes full responsibility for maintaining stock levels within agreed min-max parameters. By integrating real-time data insights and dashboarding, we provide full visibility into inventory levels, consumption trends, and supply performance. Stock at Hand solutions ensure that critical items are always available at the right moment, preventing downtime and operational disruptions.

VMI not only reduces inventory costs but also ensures a continuous and reliable supply of critical parts, helping manufacturers maintain productivity without unnecessary big stockpiles or administrative overhead.

Kitting

Efficient production processes depend on having the right items available in a structured, ready-to-use format. MAG45’s Kitting solution eliminates inefficiencies by assembling pre-configured kits tailored to specific production or maintenance needs. Instead of sourcing and handling individual parts separately, our clients receive tailored kits designed to simplify inventory handling, reduce errors, and optimize supply chain flows.

Through precise kit assembly and quality control, MAG45 ensures on-time, zero-defect deliveries, contributing to streamlined operations and reduced downtime.