At MAG45, integrated supply is more than a service, it’s a strategic enabler. We combine sourcing, inventory management, and supply chain processes around non-strategic supply into a single streamlined service. Our strategic approach minimizes risk, reduces total cost of ownership and increases reliability across your entire supply chain. With deep expertise in high-tech, med-tech, and industrial manufacturing, we help leading companies gain peace of mind and focus on what truly matters: their core business.

MAG45 as your integrated supply expert

With over 75 years of experience in machine building, MAG45 knows what it takes to run a reliable, compliant, and cost-effective supply chain. As a specialist in integrated supply, we act as an extension of your operations, combining sourcing, inventory and processes into one seamless service. Everything we do is guided by four core principles: cost-effectiveness, compliance, sustainability, and continuous innovation. This approach allows us to create long-term value and peace of mind for manufacturers operating in complex environments.

At the same time, we establish an active and ongoing joint steering committee, which will bring together all relevant stakeholders and create a communication framework. Together, we support and train your staff with new systems and ways of working, both at the outset, and as part of a continuous change management program.

Integrated supply. Strategic impact.

Integrated tail supply is no longer a tactical fix, it’s a lever for strategic value. By consolidating non-strategic spend into a single managed flow, businesses can reduce complexity, lower costs, and unlock new levels of control. At MAG45, integrated supply is designed to support long-term goals like operational efficiency, risk mitigation, and scalability across global sites.

How MAG45 delivers integrated supply

Our delivery model is hands-on, data-driven, and tailored to each client. From onboarding and supplier consolidation to inventory optimization and compliance, MAG45 manages every aspect of the tail supply chain. We embed dedicated teams, offer on-site solutions, and use smart dashboards to monitor and improve performance, creating a truly integrated partnership.

Our core principles of integrated supply

Every solution we deliver is grounded in four principles that guide our work:

- Cost-effectiveness, to deliver measurable savings

- Compliance, to safeguard quality and regulations

- Sustainability, to reduce environmental impact

- Innovation, to keep your supply chain future-ready

These principles help our clients move from complexity to clarity, and from reactive management to proactive control.

Industries that benefit from integrated supply

Our approach is built for industries where precision, compliance, and control are essential. It’s in these environments, where the cost of error is high and the demand for reliability is non-negotiable, that MAG45 adds the most value. By aligning with the unique demands of each industry, we ensure our clients benefit from a smarter, leaner, and more resilient tail supply chain.

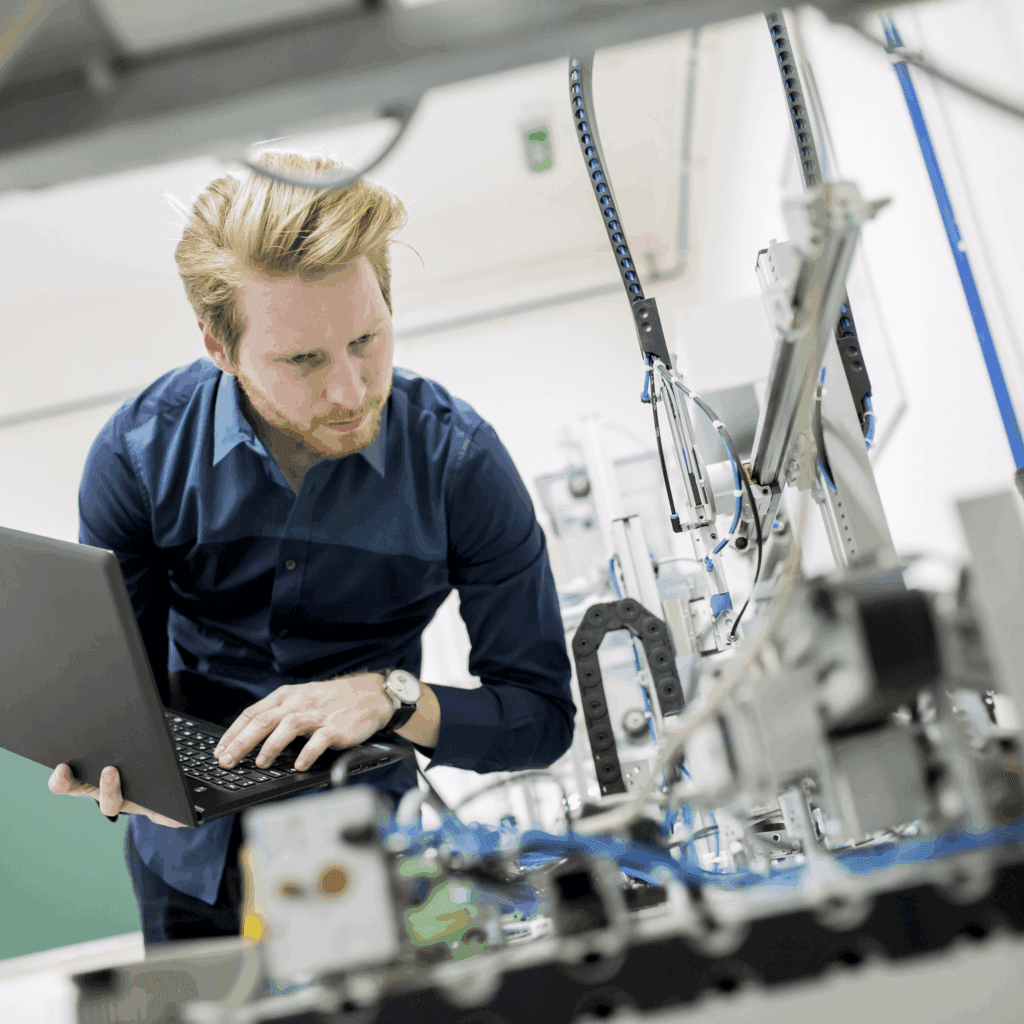

High Tech machinery

Supporting cleanroom production and BOM complexity with compliant, just-in-time deliveries.

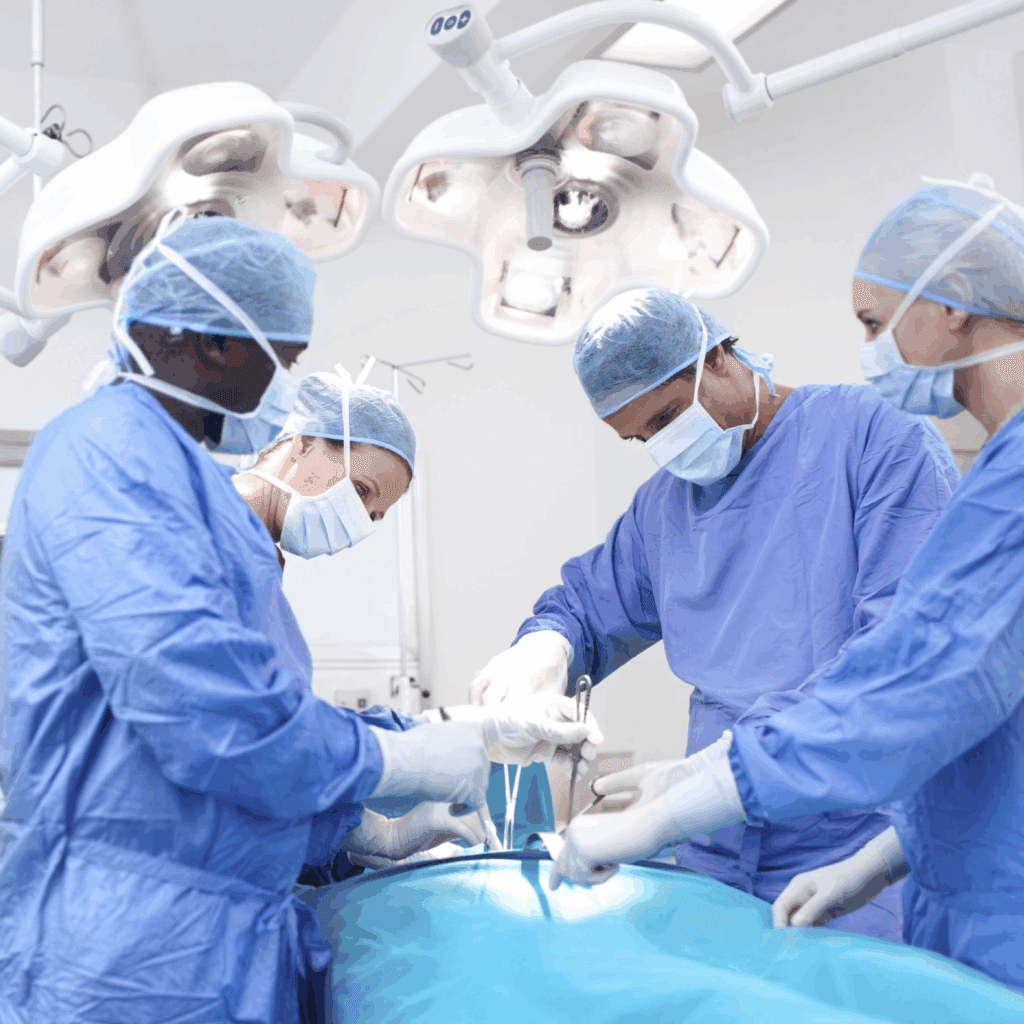

Med Tech

Ensuring full documentation, traceability, and industry-standard compliance at every step.

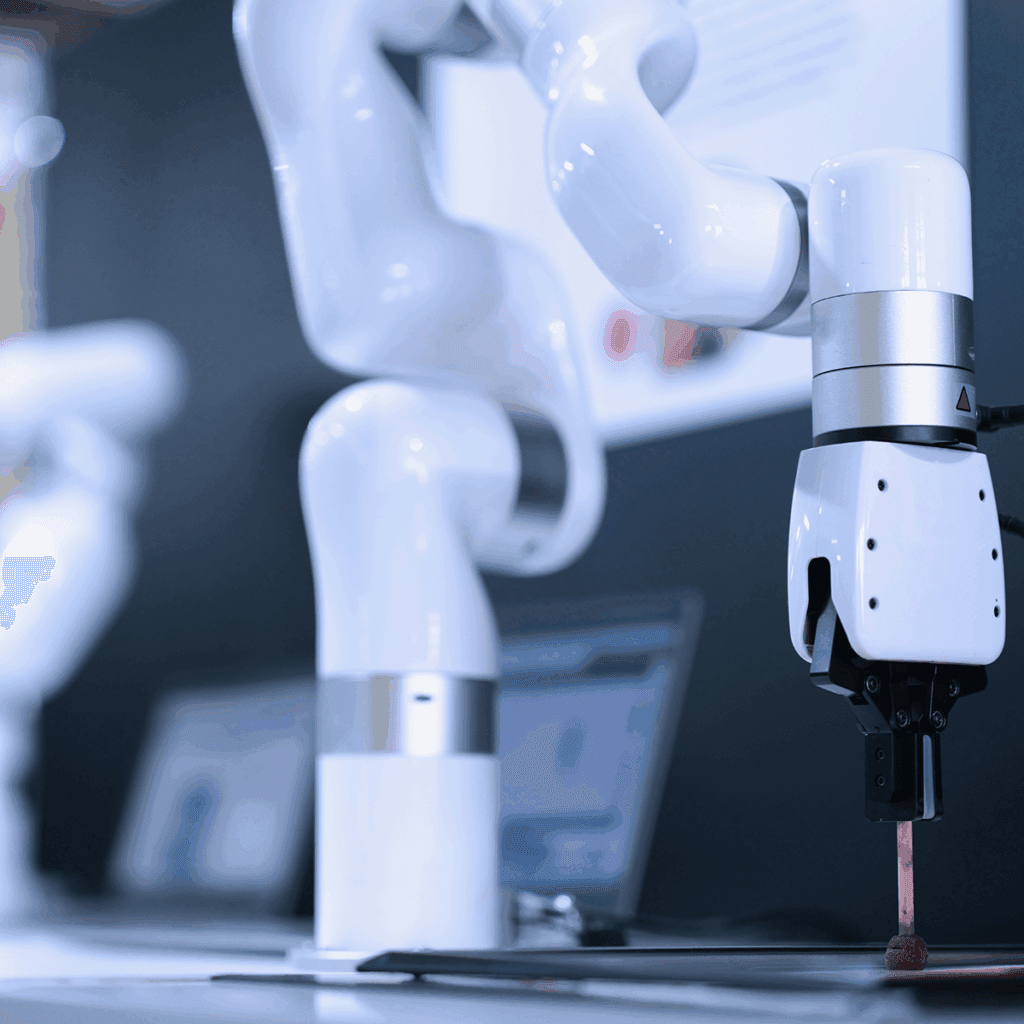

Industrial manufacturing

Structuring global supply flows, consolidating vendors, and enabling scalable procurement.

Key benefits of integrated supply

Integrated supply transforms the way businesses manage their non-strategic supply chain. At MAG45, we deliver value beyond cost savings by creating structure, control, and resilience across the entire tail supply chain. Underneath you find the key benefits our clients experience.

Reduced total cost of ownership

By consolidating suppliers, streamlining processes, and improving sourcing, we lower both direct and indirect costs across the supply chain.

Increased supply chain reliability

With full visibility, proactive monitoring, and dedicated on-site support, we help ensure consistent availability and on-time delivery of tail-items.

Improved compliance and documentation

We embed quality and compliance at every step, managing certificates, traceability, and regulatory requirements so our clients stay audit-ready.

Freed-up internal capacity

By outsourcing tail supply to MAG45, procurement, engineering, and logistics teams can focus on strategic priorities instead of day-to-day firefighting.

Scalable, future-proof supply chain

Our data-driven and modular approach adapts to evolving needs, supporting growth, digital transformation, and long-term resilience.

Case study integrated supply

Curious how integrated supply works in practice? In this case study, you’ll discover how one of our clients in the high-tech sector transformed their tail supply chain with MAG45. From fragmented sourcing and compliance risks to a fully integrated, reliable solution, this is integrated supply delivering real-world results.

Our approach to integrated supply

Every integrated supply solution starts with a structured, data-driven process. At MAG45, we guide our clients through every phase – from onboarding to optimization – to ensure seamless implementation and measurable results.

Step 1 – Strategic alignment: We begin by aligning with your business goals, project objectives, and key stakeholders. Together, we define the project scope, governance, and approach to ensure a shared vision from the start.

Step 2 – Supply chain scan & business case: Through data analysis, stakeholder interviews, and service model design, we assess your current tail supply setup. This phase identifies risks, inefficiencies, and opportunities, leading to a quantified business case for integrated supply.

Step 3 – Tailored solution design: Based on the findings, we design a customized integrated supply solution. This includes the specific solutions needed for your supply chain such as VMI, kitting and tail supply management.

Step 4 – Implementation: Our dedicated project team manages the transition. We align systems, train users, clean data, and ensure a smooth go-live with minimal disruption.

Step 5 – Operational excellence & continuous improvement: After going live, MAG45 takes full responsibility for daily operations and performance management. With on-site support, real-time dashboards, and structured reviews, we ensure stable operations while continuously improving efficiency, compliance, and cost-effectiveness.

Discover how integrated tail supply management powers your supply chain

Tail supply management is just the beginning. At MAG45, we take a fully integrated approach, combining sourcing, inventory, and process control to optimize your entire non-strategic supply chain. By connecting tail supply with our specialized services, we help you create a leaner, smarter, and more resilient operation.

Tail Supply Management

We bring structure to fragmented supplier networks by consolidating vendors, standardizing procurement, and optimizing sourcing processes. The result: lower costs, reduced complexity, and full control over your non-strategic spend.

VMI solutions

MAG45 takes full responsibility for maintaining optimal stock levels. With real-time dashboards and automated replenishment, you gain visibility, reduce stockouts, and avoid overstock, freeing up time and resources.

Kitting

We deliver pre-assembled kits tailored to your production or maintenance process. From cleanroom kits to service sets, our kitting solutions improve accuracy, reduce downtime, and streamline internal logistics.

Why choose MAG45?

Leading manufacturers choose MAG45 because we go beyond traditional procurement. We are not only a one-stop shop for tail spend, we also provide strategic, compliant, and scalable solutions that create real impact.

One partner for all tail spend

We manage the full scope of your non-strategic supply—from sourcing to logistics and compliance—so you can focus on your core business.

Machine building DNA

With deep experience in high-tech, med-tech, and industrial manufacturing, we understand the standards, risks, and realities of your production environment.

Data-driven and performance-focused

Our smart dashboards, KPIs, and insights deliver continuous improvement and measurable value across your supply chain.

Built-in compliance and sustainability

We ensure every step meets regulatory standards and supports your sustainability goals, from cleanroom packaging to green supply chain practices.