– Arkadiusz (Arek) Kościołowski, Country Manager Poland at MAG45

From a single CNC machine to a fully equipped production site – and from day one, MAG45 was there to support with tool supply, vending automation, and now: tool reconditioning. The result? Cost savings of up to 80%, full visibility, and the foundation for a smarter, more circular supply approach.

A fast-growing site, supported from the start

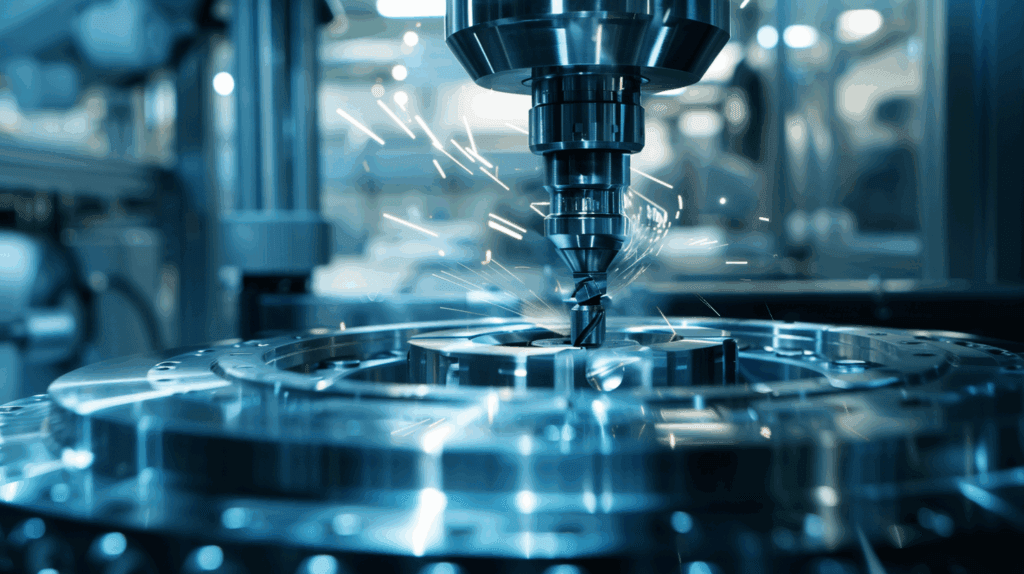

When one of MAG45’s manufacturing partners launched a new production site in 2023, it started with just one CNC machine. Today, the facility operates dozens and continues to grow. MAG45 supported the site from the very beginning – first by supplying CNC tooling and holders, measuring tools, and production fluids. Then, by helping the customer manage assortments through a vending machine system. Most recently, MAG45 introduced a reconditioning loop for high-value cutting tools.

This setup is remarkable not just for its rapid growth, but because value-adding solutions such as tool reconditioning and call-off orders were integrated right from the ramp-up phase.

“Even before series production began, we were already in discussions with tool suppliers and the customer’s engineering team about which tools could be reconditioned,” explains Arkadiusz (Arek) Kościołowski, Country Manager Poland at MAG45. The team sent the first batch of tools for testing immediately after validation, enabling faster implementation and reduced upfront costs.

High-value tools, high-impact savings

The reconditioning program began with gun drills and was quickly extended to specialized milling tools. While these represent only about 10% of the total tool range, they account for nearly 30% of overall tool costs – making the impact substantial.

Reconditioning drills costs around 20% of the price of a new tool. Milling tools are more complex to rework, but still deliver savings of around 50% per unit.

“Some of these tools cost over €1,000 each. If we can recondition them up to three times, the savings really add up.”

ESG impact: sustainability built into the supply chain

Beyond financial benefits, reconditioning directly contributes to sustainability goals by reducing tool waste and minimizing the use of new resources. Manufacturing new tools consumes raw materials, energy, and water. Reconditioning breaks that cycle by keeping materials in use: a tool can typically be reconditioned up to three times with guaranteed quality – and in some cases even five – while maintaining the same performance standards. This can cut emissions dramatically, avoiding up to 90% of the CO₂ associated with producing new tools.

“The old linear model of buy-make-dispose no longer works,” explains Eftychia Konstantinidou, ESG Specialist at MAG45. “When a customer chooses reconditioned tools, it creates a ripple effect: suppliers adapt their processes, and tier 1 and tier 2 partners improve as well. Each step influences the next, creating momentum for sustainability throughout the entire value chain.”

“When a customer chooses reconditioned tools, it creates a ripple effect: suppliers adapt their processes, and tier 1 and tier 2 partners improve as well. Each step influences the next, creating momentum for sustainability throughout the entire value chain.”

Logistics and control, fully managed by MAG45

The reconditioning process is managed end-to-end by MAG45’s on-site team. Used tools are collected, sorted, and shipped directly to the supplier for rework. Once returned, they’re quality-checked and stored separately in vending machines. When operators retrieve a tool, they can select between a new or reconditioned version – ensuring full transparency and process control.

“Thanks to the vending setup, everything is visible. We know which tools are in use, which are returned, and when they need to be re-ordered or reconditioned,” Arek adds.

Why this works – and how others can benefit

According to Arek, close cooperation with engineering is essential. CNC programs must be adapted to match reconditioned tool dimensions, and the production team should be involved in testing and validation. “The process isn’t complex, but it requires coordination and trust. When both sides commit, results come quickly,” he says.

The benefits are clear:

- Up to 80% lower tool cost for selected items.

- Shorter lead times for critical tools.

- Fewer stockouts and less waste.

- Full transparency and control via vending machines.

- Measurable ESG impact through circular material use.

Interested?

Want to know how reconditioning could work at your site? Reach out to your MAG45 contact and learn how we can help make your tooling smarter, more cost-effective, and more sustainable.