Efficiency through customization

Simplify your supply chain with MAG45’s kitting solutions—custom-assembled kits that deliver the right parts, at the right time, in the right format. Whether it’s for production, maintenance, or cleanroom environments, our kitting solutions reduce handling time, eliminate errors, reduce the administrative burden, and streamline operations. From standard kit assembly to fully tailored packaging, we turn complexity into efficiency.

MAG45 as your kitting and fulfillment expert

MAG45 is more than a kitting company, we are a strategic tail supply chain partner. As part of our integrated supply approach, our kitting solutions are designed to meet the highest standards. We support global manufacturers in high-tech, med-tech, and industrial sectors by delivering custom-made kits that are production-ready, quality-controlled, fully compliant, and aligned with your specific operational needs.

What is kitting?

Kitting in fulfillment and logistics refers to the process of pre-assembling individual parts into ready-to-use kits tailored to specific production or maintenance needs. Instead of handling multiple loose components, our clients receive complete, structured kits. For engineers, it means less time spent on searching for the items they need. Kits reduce errors, speed up operations, and simplify warehouse handling. It’s a key element in streamlining fulfillment and ensuring continuity in complex supply chains..

The different types of kitting

At MAG45, we offer four specialized kitting solutions, each tailored to specific operational and industry requirements:

- Tail kits – Containing pre-assembled items that are part of your Bill of Materials (BOM). Designed to streamline production and assembly by grouping non-strategic components into ready-to-use kits. Ideal for environments with complex BOMs.

- Service kits – Built for field maintenance and repairs. These kits include all required parts in one package, often with custom foam inlays, clear labeling, and usage documentation.

- Cleanroom kits – Developed for high-compliance industries like high-tech and med-tech. Assembled and packed under strict cleanroom protocols to ensure contamination-free delivery.

- Special packaging – From custom-sized boxes to anti-static bags and sealed pouches, MAG45 offers tailor-made packaging to protect sensitive parts and meet unique handling needs.

Each kit type simplifies logistics, reduces errors, and ensures consistent quality across your supply chain.

Industries that benefit from kitting solutions

Kitting solutions are essential in industries where precision, compliance, and efficiency are highly prioritized. In high-tech, kits support cleanroom assembly with strict handling requirements. In med-tech, kitting ensures traceability and compliance with industry standards like FDA and MDR. In industrial manufacturing, kitting brings structure and repeatability to large-scale, multi-site production. MAG45 specializes in these complex environments—where kitting is not just convenient, but critical.

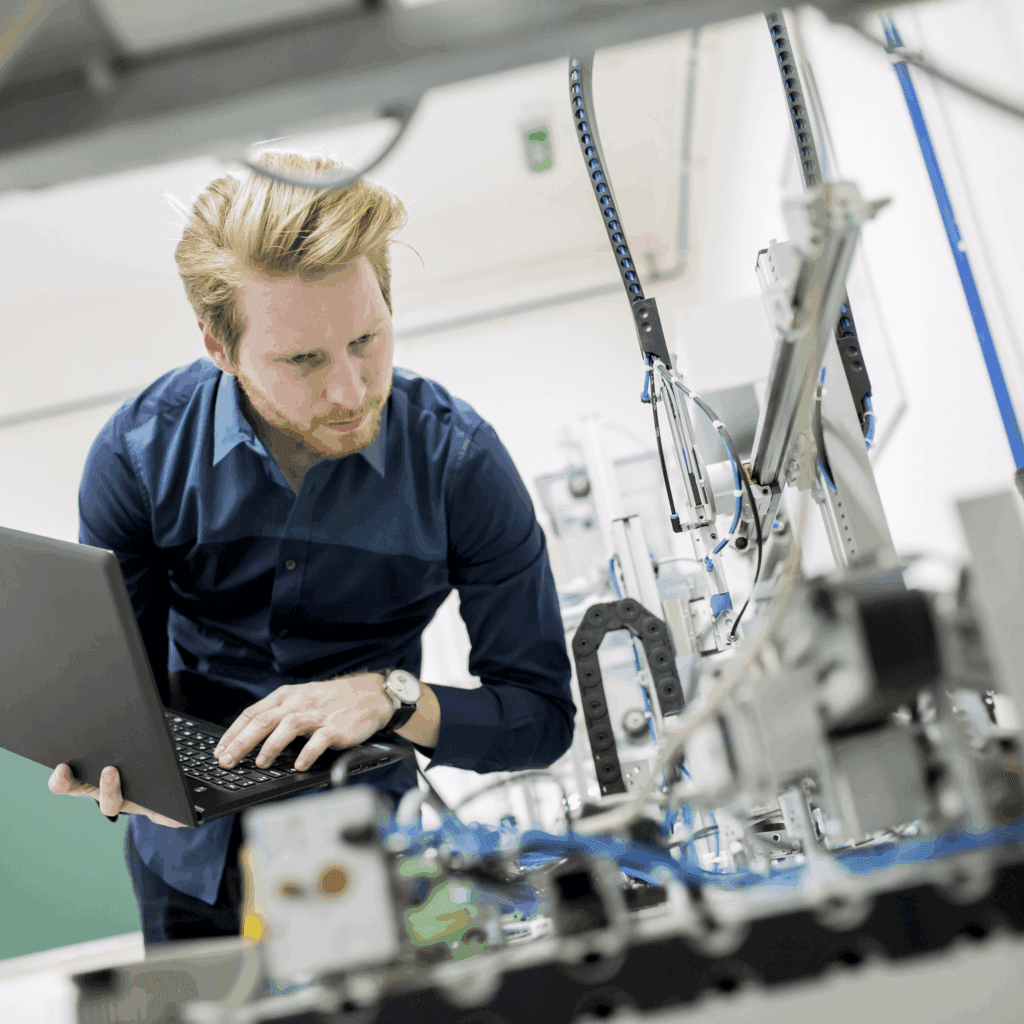

Kits in High Tech machinery

Kitting supports cleanroom compatibility, part integrity, and smooth integration into complex assembly processes in High Tech production

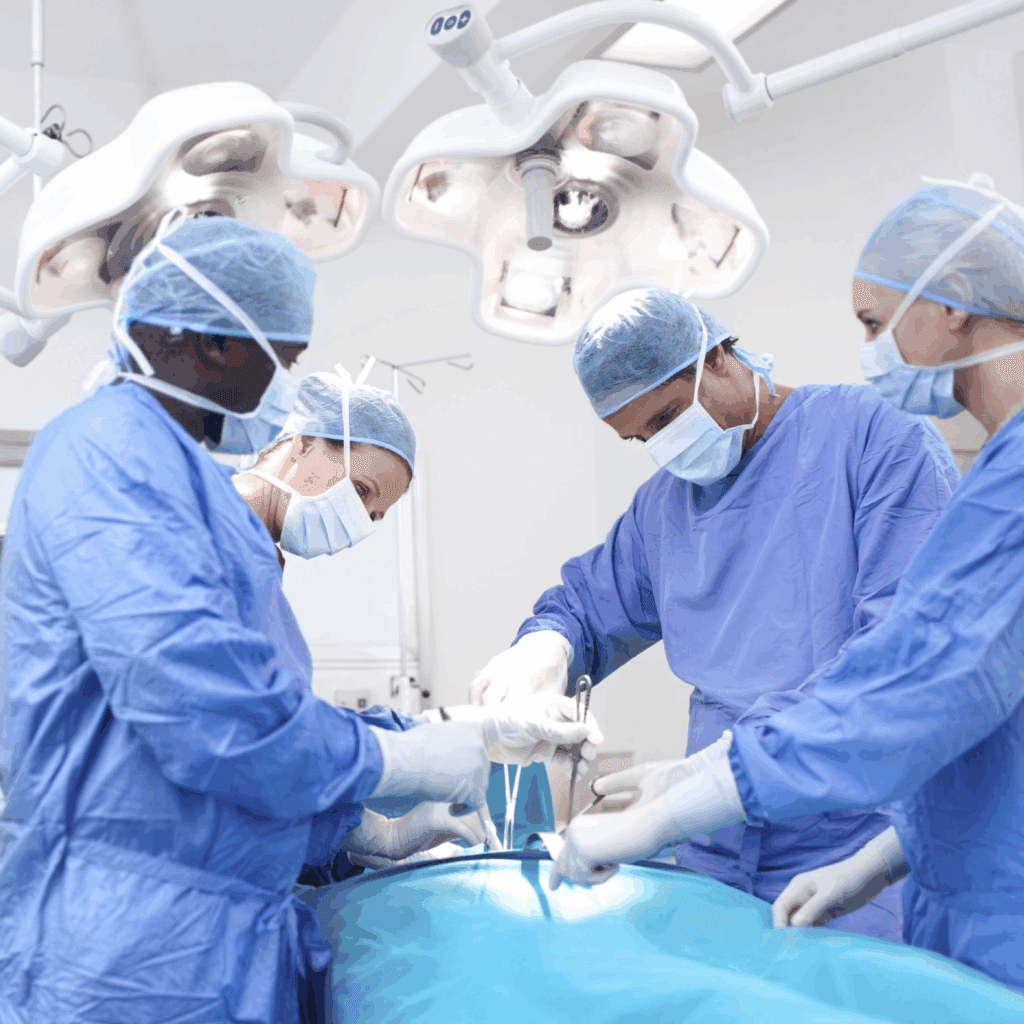

Kits in Med Tech

MAG45’s kits include CoCs, SDS and labeling—ensuring every component is audit-ready and fits regulatory frameworks like MDR or FDA in the Med Tech industry.

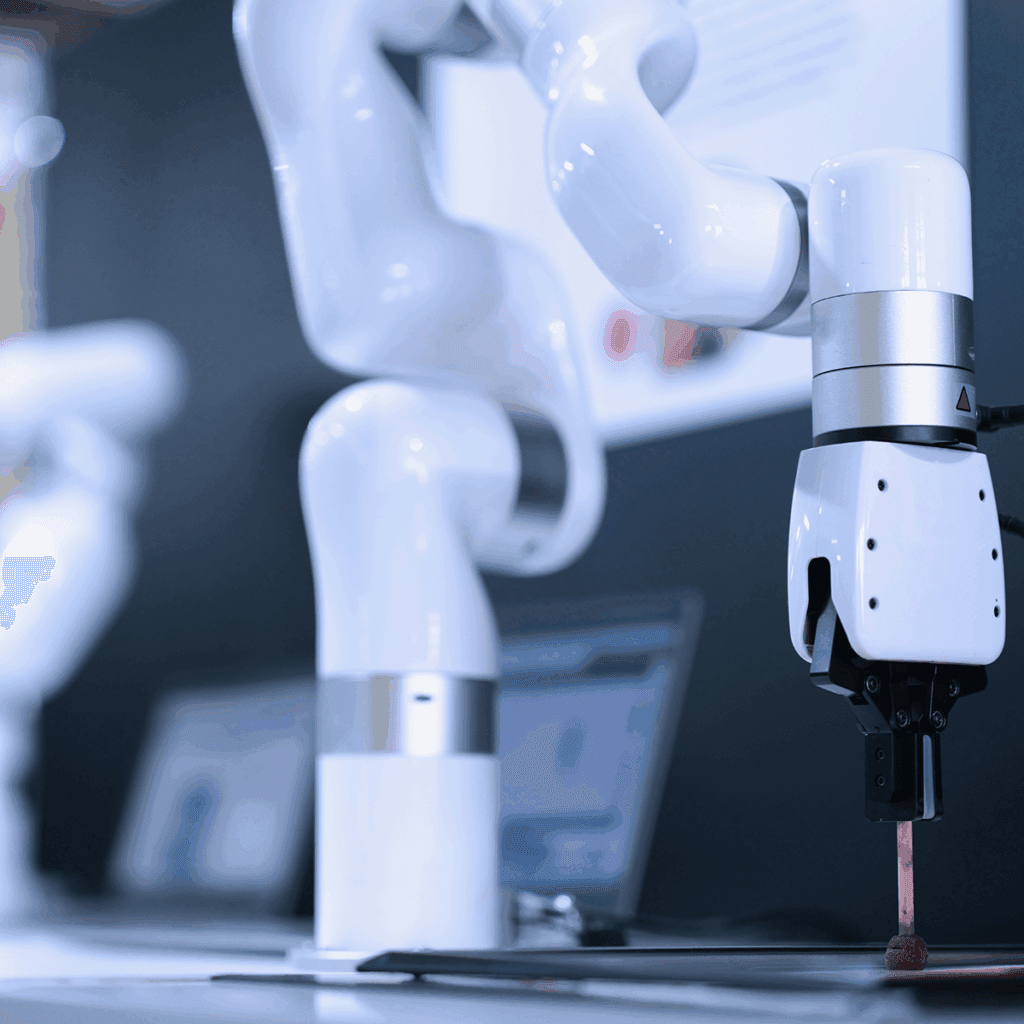

Kits in Industrial manufacturing

Kitting standardizes component delivery, reduces downtime, and simplifies warehouse handling for industrial manufacturers.

Benefits of kitting in manufacturing

Kitting plays a vital role in optimizing manufacturing processes by reducing inefficiencies, minimizing errors, and ensuring production continuity. By assembling parts into ready-to-use kits, manufacturers gain better control, speed, and quality in their operations.

Increased assembly efficiency

Kits eliminate the need to search for individual components, saving time on the production floor and speeding up assembly processes.

Reduced risk of errors and shortages

With pre-configured kits, every item is checked and confirmed, reducing the chance of missing parts and creating 100% OTIF.

Lower handling costs

Kitting reduces the number of pick-and-pack transactions, which lowers overall warehouse labor costs.

Improved supply chain control

Kitting provides greater visibility and traceability across your supply chain, ensuring that everything is in place when and where it’s needed.

Enhanced customization

From cleanroom packaging to field service kits, kitting can be tailored to specific manufacturing requirements.

Case study kitting

Curious how kitting services can transform your operations? Discover how MAG45 helped a global manufacturer streamline production with tailored kitting solutions—improving efficiency, reducing downtime, and ensuring compliance in a complex manufacturing environment.

The kitting process in manufacturing

At MAG45, we design the kits together with you, so they align seamlessly with your operations. From initial intake to final delivery, every step is built to ensure precision, efficiency, and compliance – whether for production, maintenance, or cleanroom environments.

- Defining kit requirements – We start by analyzing your Bill of Materials (BOM), usage data, and operational needs to define kit structure, packaging requirements, and compliance criteria.

- Streamlining sourcing – We consolidate all components from various suppliers into a single, reliable flow—reducing complexity, lead times, and risk.

- We assemble and validate the kit – Our teams build the kits according to strict specifications, checked for quality, compliance, and usability. If needed within cleanroom conditions.

- We deliver your kit, ready to use – The kit is delivered exactly where and when needed, fully documented and production-ready, helping you save time, reduce downtime, and improve the workflow.

Discover how kitting powers your integrated supply chain

Kitting is just one part of a smarter, more connected supply chain. At MAG45, we integrate sourcing, inventory and processes into one seamless service, giving you full control, fewer disruptions, and maximum efficiency.

Tail Supply Management

By offering tail supply management, we take full ownership of your tail supply. From consolidating suppliers to optimizing purchasing flows. The result: less complexity, lower costs, and a more resilient supply chain.

VMI solutions

With VMI, we ensure stock availability without the burden of manual tracking. We monitor usage, manage replenishment, and secure critical parts. What do you get? More peace of mind and focus on your core business.

Why choose for MAG45 for kitting services?

Companies in high-tech, med-tech and industrial manufacturing choose MAG45 because we deliver more than just kits. We deliver control, compliance and continuity across global operations, ultimately resulting in more peace of mind for the people involved.

Integrated supply chain expertise

With 75+ years of tail supply experience in complex manufacturing environments.

Compliance built-in

From CoCs to cleanroom packaging—we manage every compliance detail so you don’t have to.

Industry-specific expertise

With deep knowledge of high-tech, med-tech and industrial manufacturing, we build kits that fit your reality.

Global presence, local execution

We support international operations with on-site experts and a service model built for complex, multi-site environments.

FAQ

What is the difference between kitting and bundling?

Kitting involves assembling individual items into a ready-to-use kit for operational or production purposes. Bundling is typically used for sales or marketing—grouping products for commercial packaging.

What is the difference between kitting and assembly?

Kitting prepares all necessary components in a structured package for later use. Assembly goes a step further, combining those components into a finished or semi-finished product. Be aware: at MAG45 we also offer kitting solutions that contain assembled semi-finished products.

Where does kitting fit into the supply chain?

Kitting is part of the fulfillment and logistics process. It sits between sourcing and final use, helping streamline production, reduce errors, and improve delivery accuracy. Besides the supply chain, kits are also used in other places, such as maintenance.